Shaft Gd T Drawing

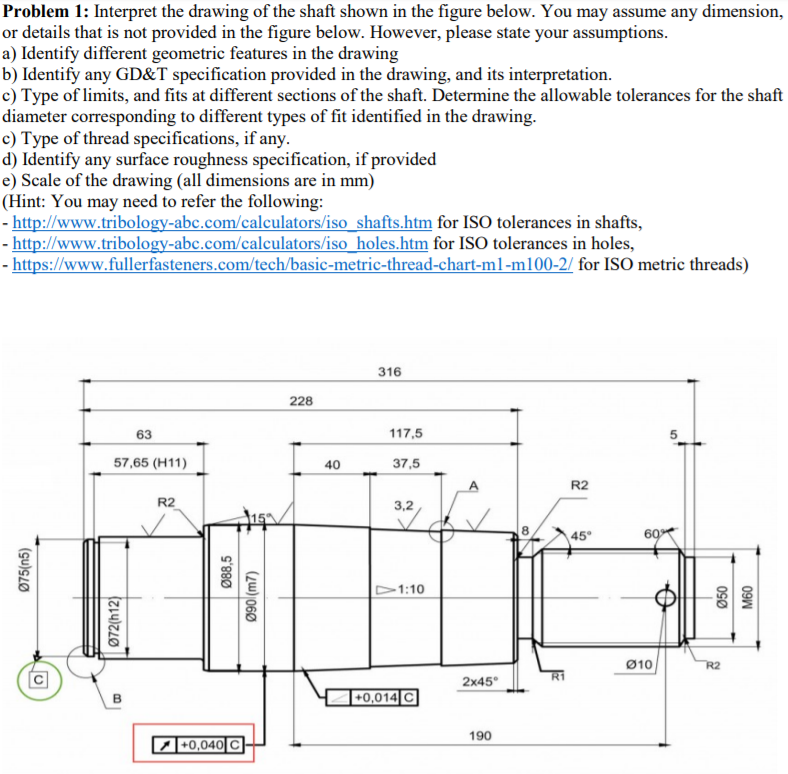

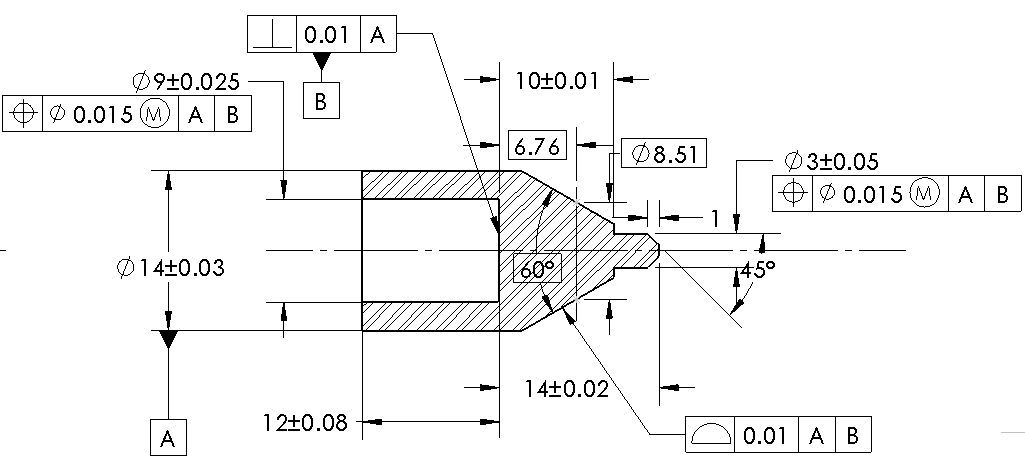

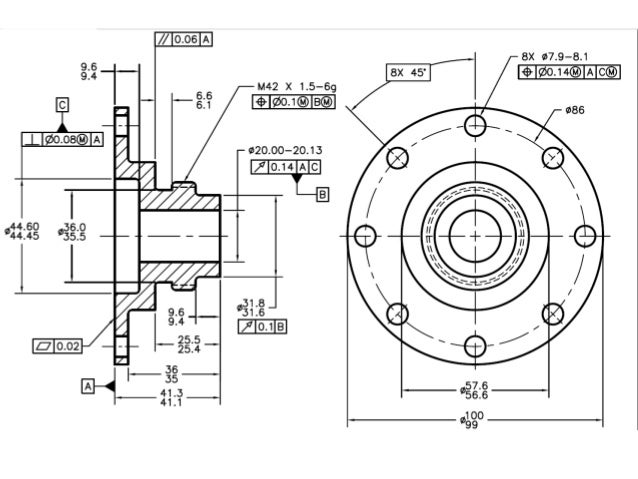

This gd t control allows the diameter tolerances of the part to be opened up much larger and better controls the entire length of the bore.

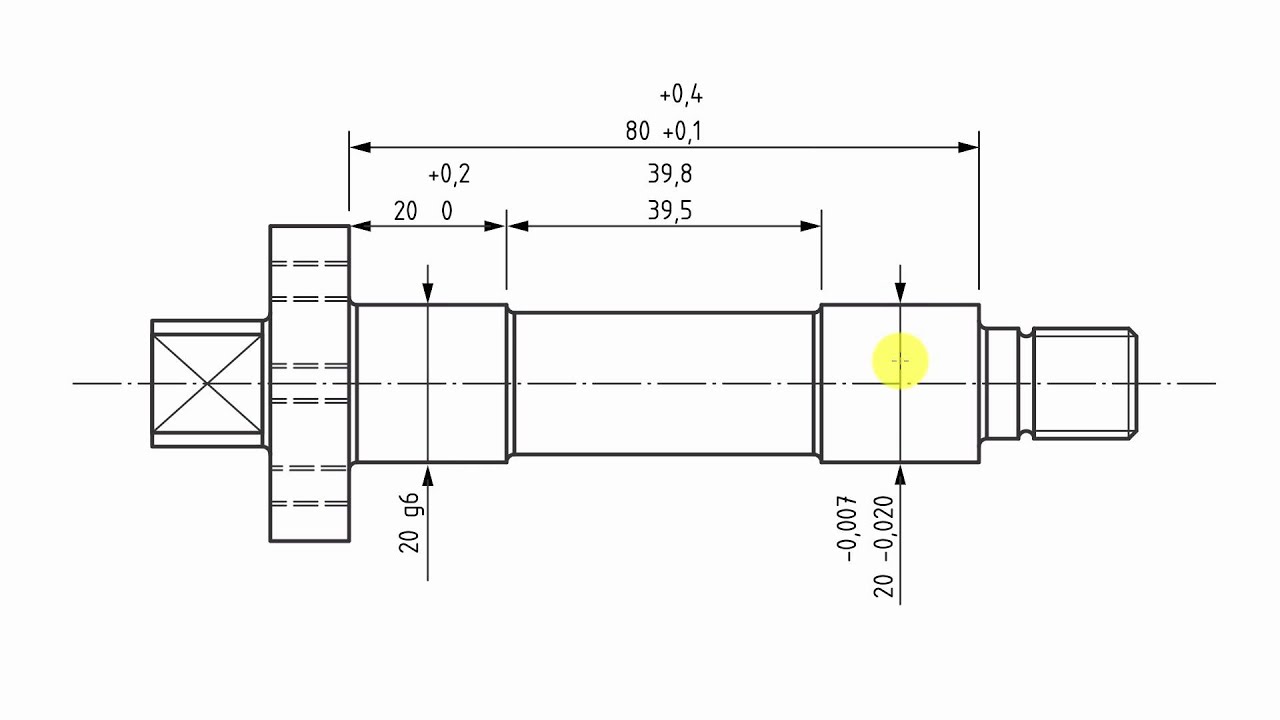

Shaft gd t drawing. Asme y14 5 2009 version of geometric dimensioning tolerancing gd t standard on engineering drawing and related documentation practices states in its foreword thus this revision contains paragraphs that give a stronger admonition than in the past that the fully defined drawing should be dimensioned using gd t with limit dimensioning reserved primarily for the size dimensions for. Do not specify a 90 degree angle since it is assumed. Refer to the provided reference documents to complete this assignment. If a shaft is 10 0 05 inch what is its maximum and least material conditions.

In this post we cover some important rules basic concepts and gd t symbols that set you up containing. If extra room is. Runout is how much one given reference feature or features vary with respect to another datum when the part is rotated 360 around the datum axis. This assignment highlights gd t concepts you need to know for working in industry.

Controlling cylindricity without gd t symbol controlling the circularity and the straightness of the bore with cylindricity. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each. This video is from my free introduction to. Hole f 32 upper deviation 0 021 lower deviation 0 0 shaft f 32 upper deviation 0 029 lower deviation 0 016 3.

When it comes to gd t there is a lot of information available describing how to apply gd t to the drawing. Geometric dimensioning and tolerancing gd t is a system for defining and communicating engineering tolerances it uses a symbolic language on engineering drawings and computer generated three dimensional solid models that explicitly describe nominal geometry and its allowable variation. Find t h t s allowance c max i max and what kind of fit it is. Yes mmc or lmc applicable.

Whenever possible leave gd t work to the manufacturing experts and do not describe manufacturing processes in the engineering drawing. A simple example of dimensional tolerancing of a shaft illustrating the shortcomings of dimensional tolerancing. Dimensions and tolerances are valid at 20 c 101 3 kpa unless stated otherwise.